How Structure and Coverage Shape Catalyst Reactivity

In the relentless pursuit of more efficient and selective catalysts, the scientific community is turning its gaze toward a phenomenon that has long complicated surface chemistry: the dense coverage of adsorbates on catalyst surfaces. When molecules form a crowded layer atop catalytic materials, they don’t merely occupy sites passively. Instead, these adsorbates provoke dynamic structural […]

In the relentless pursuit of more efficient and selective catalysts, the scientific community is turning its gaze toward a phenomenon that has long complicated surface chemistry: the dense coverage of adsorbates on catalyst surfaces. When molecules form a crowded layer atop catalytic materials, they don’t merely occupy sites passively. Instead, these adsorbates provoke dynamic structural transformations that ripple across the surface and even penetrate the entire catalyst nanoparticle. This intricate interplay between adsorbate coverage and catalyst morphology heralds a paradigm shift in understanding catalytic activity, selectivity, and stability under realistic operating conditions.

Recent investigations underscore the profound implications that adsorbate-induced structural changes have on catalytic function. Unlike idealized, static models traditionally employed in catalyst design, real surfaces under reaction conditions are far from inert. Adsorbates—be they reactants, products, intermediates, or spectators—imbue the surface with a plasticity that can modify atomic arrangements, electronic states, and thus reactivity. To accurately capture such complexity, a new generation of computational methodologies is rising, aiming to bridge the gap between theoretical predictions and experimental realities.

At the forefront of this revolution is the integration of machine learning techniques into in silico catalyst modeling. These approaches leverage vast datasets to discern subtle patterns that govern adsorbate behavior and resultant structural reorganizations. By transcending conventional static-density functional theory calculations, machine learning accelerates the exploration of atomic configurations, enabling simulations that approach practical time and length scales necessary for realistic catalyst modeling.

.adsslot_lV1TWw7b9j{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_lV1TWw7b9j{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_lV1TWw7b9j{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

Central to this endeavor is the recognition that adsorbate coverage can induce local, and even global, structural transformations in nanoparticles. These changes extend beyond surface rearrangements to include particle reshaping, facet evolution, and defect formation. Such modifications can dramatically alter active site availability and electronic properties, leading to enhanced or diminished catalytic performance. Addressing this interplay requires computational frameworks capable of dynamically adapting to evolving surface states.

Current modeling efforts grapple with numerous obstacles. Capturing the full spectrum of adsorbate-induced deformation demands simulations that can handle the combinatorial complexity of multicomponent adsorbate layers while accounting for environmental factors such as temperature, pressure, and solvent effects. Furthermore, achieving predictive accuracy necessitates models that can integrate kinetic and thermodynamic considerations, thus reflecting dynamic surface equilibria during catalysis.

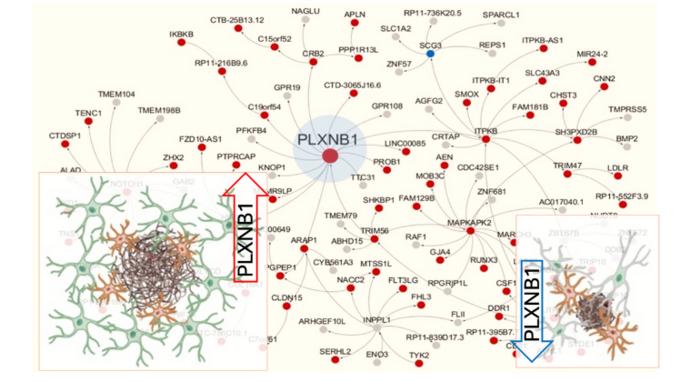

Progress is emerging through the development of hybrid approaches that meld quantum mechanical precision with machine learning speed. For instance, neural network potentials trained on high-fidelity quantum calculations enable rapid evaluation of energetics across vast configurational spaces. Similarly, graph-based models that encode atomic connectivity offer new insights into structural motifs that favor reactivity. These advances collectively inch closer to realistic simulations of catalyst behavior under operative loads.

The path forward demands a coordinated convergence of several critical areas. First, artificial intelligence must be deeply woven into catalytic modeling workflows, facilitating adaptive learning and real-time refinement of predictive models as new data emerges. Second, robust catalysis informatics infrastructure is essential to curate, manage, and disseminate extensive datasets spanning experimental measurements and computational outputs. This will democratize access and encourage cross-disciplinary collaborations.

Complementing computational advances, synergistic partnerships with experimental characterization techniques will be pivotal. State-of-the-art microscopy and spectroscopy tools provide invaluable in situ snapshots of catalyst morphologies and adsorbate distributions, serving as benchmarks for validating and refining computational predictions. Such feedback loops will accelerate the iterative improvement of models, increasing their reliability and relevance.

Adaptive modeling frameworks that can respond to evolving catalyst environments represent a visionary goal. By incorporating feedback from reaction conditions, such models can predict structural changes in real time, revealing emergent phenomena such as sintering, reconstruction, or poisoning. These insights are indispensable for designing catalysts that maintain activity and selectivity over prolonged operation.

The implications of mastering adsorbate-induced phenomena extend beyond academic curiosity. Improved catalysts benefiting from informed design hold promise for transforming industrial processes, enhancing energy efficiency, and reducing environmental footprints. For example, controlling adsorbate coverage and structure-reactivity relationships may unlock breakthroughs in carbon dioxide reduction, ammonia synthesis, or hydrocarbon upgrading.

Chen and Mavrikakis’s recent study epitomizes this transformative trajectory by charting a comprehensive roadmap linking molecular-level understanding to macro-scale catalytic behavior. Their work illuminates how advanced modeling can dissect the nuanced roles of adsorbate interactions, structural flexibility, and environmental context. Importantly, it underscores the imperative of embracing complexity rather than oversimplifying real catalytic systems.

Looking ahead, the integration of multidisciplinary expertise—encompassing surface science, computational chemistry, machine learning, and materials characterization—will be vital. Emerging scholars and seasoned researchers alike must harness these synergies to unravel the multifaceted nature of catalyst surfaces dense with adsorbates. Only then can the dream of rational, predictive catalyst design become a routine reality.

The revolution in catalyst modeling beckons a future where materials can be tailored with atomic precision, dynamically adapting to their reaction landscapes. This vision, underpinned by a balanced amalgamation of advanced computation and experimental validation, paints an inspiring picture of sustainable chemical manufacturing. It is a testament to the power of interdisciplinary innovation in driving scientific frontiers.

As we push boundaries, challenges remain. Achieving full predictive control over adsorbate coverage effects demands ever larger computational resources, improved algorithms, and richer datasets. Equally, nuanced experimental validation of predicted surface transformations remains complex and resource-intensive. Bridging these divides will require persistent innovation and open scientific dialogue.

Nonetheless, the momentum is undeniable. By harnessing emerging in silico methodologies infused with artificial intelligence, catalysis research is set to unlock hidden dimensions of surface chemistry, fundamentally altering how materials are designed and utilized. The dynamic world of adsorbate-covered catalysts is no longer an enigma but a fertile ground for discovery and application.

In summary, understanding and modeling the impact of adsorbate-induced structural changes is fast becoming a key frontier in heterogeneous catalysis. The convergence of machine learning with atomistic simulations heralds unprecedented opportunities to demystify complex surface behaviors. Chen and Mavrikakis’s insights offer a beacon guiding the catalysis community toward a new era of intelligent, adaptive catalyst design capable of tackling pressing energy and environmental challenges.

Subject of Research: Modeling adsorbate-induced structural and coverage effects on the reactivity of realistic heterogeneous catalysts.

Article Title: Modeling the impact of structure and coverage on the reactivity of realistic heterogeneous catalysts.

Article References:

Chen, B.W.J., Mavrikakis, M. Modeling the impact of structure and coverage on the reactivity of realistic heterogeneous catalysts.

Nat Chem Eng 2, 181–197 (2025). https://doi.org/10.1038/s44286-025-00179-w

Image Credits: AI Generated

DOI: https://doi.org/10.1038/s44286-025-00179-w

Tags: adsorbate coverage effectsadsorbate-induced changes in reactivitycatalyst nanoparticle morphologycatalyst reactivitycomputational methodologies in catalyst designdynamic structural transformationsexperimental realities in catalysismachine learning in catalysisplasticity of catalyst surfacesreal-world catalytic conditionsselective catalysts developmentsurface chemistry challenges

What's Your Reaction?