Boosting Strength in 2D Materials: An AI-Powered Approach to Enhanced Material Design

In a groundbreaking advancement within materials science, researchers from ShanghaiTech University have developed an innovative AI-driven framework designed to enhance the mechanical properties of two-dimensional patterned hollow structures (2D-PHS). This cutting-edge research emphasizes the significance of 2D-PHS, a class of metamaterials characterized by their extraordinary mechanical attributes and lightweight structure. 2D-PHS, composed of a solid […]

In a groundbreaking advancement within materials science, researchers from ShanghaiTech University have developed an innovative AI-driven framework designed to enhance the mechanical properties of two-dimensional patterned hollow structures (2D-PHS). This cutting-edge research emphasizes the significance of 2D-PHS, a class of metamaterials characterized by their extraordinary mechanical attributes and lightweight structure. 2D-PHS, composed of a solid matrix interspersed with periodically arranged hollows, epitomize the future of material design by striking a balance between reduced density and optimized strength, thereby opening up new avenues for high-performance lightweight applications, particularly in the aerospace sector.

The mechanical behavior of these advanced materials is pivotal in numerous engineering contexts, where weight is a critical factor, such as aircraft wings and fuselage structures. The traditional challenge has been to maintain high strength while minimizing mass. However, with the integration of 2D-PHS into structural designs, engineers can achieve remarkable strength-to-weight ratios, enhancing both performance and efficiency. Existing solid materials often fall short in delivering optimal performance in demanding applications, making the exploration of 2D metamaterials not just advantageous but essential.

The pioneering research led by Professor Shengjie Ling’s team and Dr. Yu Wang provides a comprehensive examination of the mechanical properties of 2D-PHS. These materials possess a unique combination of lightweight design, extensive deformability, and impressive energy dissipation capabilities, rendering them suitable for various applications ranging from aerospace components to biological tissue engineering and impact-resistant devices. The versatility of 2D-PHS positions them as a game-changer in fields that require both flexibility and resilience under cyclical or repetitive stresses.

.adsslot_tW5dynjbUH{ width:728px !important; height:90px !important; }

@media (max-width:1199px) { .adsslot_tW5dynjbUH{ width:468px !important; height:60px !important; } }

@media (max-width:767px) { .adsslot_tW5dynjbUH{ width:320px !important; height:50px !important; } }

ADVERTISEMENT

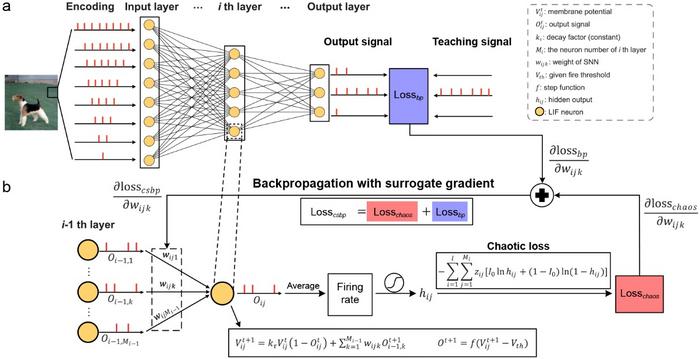

At the heart of this transformative work lies the AI-driven framework which adeptly melds experimental methodologies with computational modeling. By systematically analyzing critical parameters influencing the mechanical properties of 2D-PHS—such as the arrangement, size, and shape of hollow structures—the researchers harness machine learning algorithms to tailor these attributes effectively for practical applications. This approach allows for the optimization of material design through extensive simulations, significantly reducing reliance on exhaustive experimental iterations.

The findings reported by the ShanghaiTech research team demonstrate a substantial enhancement in material performance. Specifically, their AI-based framework yielded a 4.3% improvement in average stress uniformity alongside a remarkable 23.1% reduction in maximum stress concentrations. This triple-pronged focus on strength optimization not only empowers materials to withstand higher loads but also extends their longevity and reliability in varying applications. The tensile strength of optimized 2D-PHS samples, for instance, showed an impressive increase from an initial average of 5.9 MPa to 6.6 MPa when subjected to 100% strain, showcasing the transformative potential of AI in materials research.

Looking ahead, the research team aims to refine the model’s scalability and generalization capabilities. One proposed strategy involves the development of universal neural network architectures to decrease dependence on substantial datasets tailored to specific training contexts. This broadening of the framework is set to not only enhance the model’s adaptability across diverse engineering landscapes but also its capacity to integrate optimization parameters from multiple physical domains.

Further advancements will focus on incorporating nonlinear simulations and executing destructive experiments designed to probe the failure mechanisms of materials subjected to various loading conditions. This research holds the promise of uncovering profound insights into the dynamic behavior of 2D-PHS across a range of applications, meticulously evaluating how different materials and configurations respond to mechanical stresses in real-world scenarios.

The strategic direction proposed by the research team involves extending this AI-driven framework to explore three-dimensional structures. Such a leap in complexity will undoubtedly furnish engineers with immense versatility, allowing for designs that can cater to multifaceted application requirements, effectively addressing the escalating demand for innovative materials in sectors like aerospace and automotive engineering.

In conclusion, the introduction of an AI-enhanced design framework for 2D-PHS marks a pivotal moment in materials science, facilitating the streamlined creation of lightweight materials with tailored mechanical properties. As industries increasingly seek to innovate and elevate product performance while managing weight, the implications of this research are far-reaching. This work not only encapsulates current advancements in materials engineering but also heralds the next generation of structural materials that meet the demands of high-performance applications across various industries.

With the recent publication of these findings in the prestigious journal Materials Futures, researchers are poised to inspire further investigation and application of AI in the material sciences, illustrating how artificial intelligence serves as an invaluable ally in the quest for material optimization.

Subject of Research: AI-driven optimization of two-dimensional patterned hollow structures (2D-PHS)

Article Title: How AI Is Making 2D Materials Stronger: An AI-driven Framework to Improve Material Design

News Publication Date: [Insert Publication Date Here]

Web References: http://dx.doi.org/10.1088/2752-5724/ade732

References: Shan, Yicheng, et al. AI-Driven Generative and Reinforcement Learning for Mechanical Optimization of Two-Dimensional Patterned Hollow Structures. Materials Futures. DOI: 10.1088/2752-5724/ade732

Image Credits: Credit: This study was a joint effort between Professor Shengjie Ling’s team and Dr. Yu Wang.

Keywords

Two-dimensional materials

Artificial intelligence

Metamaterials

Mechanical engineering

Aerospace applications

Tags: 2D patterned hollow structuresadvanced materials researchaerospace material innovationsAI-driven material designfuture of material sciencehigh-performance lightweight materialslightweight structural applicationsmechanical behavior of 2D-PHSmechanical properties of metamaterialsShanghaiTech University breakthroughsstrength-to-weight ratio in engineeringtwo-dimensional materials

What's Your Reaction?