Navigating affordable approaches to cell therapy clinical trials

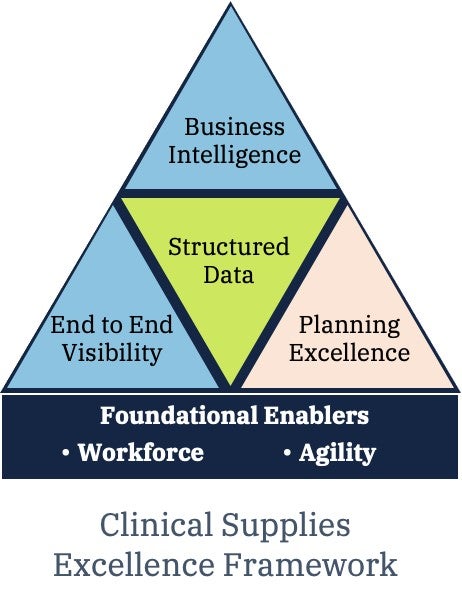

By Luisa Sterkel & Joana Loureiro, Tenthpin Consultants and Dr. Frank Altznauer Chief Industry Advisor at Tenthpin Despite the now evident impact of cell therapies on the standard treatment of patients suffering from different medical conditions, the progress of cell therapies in development gets hindered by challenges such as regulatory framework gaps, stringent Food and Drug Administration (FDA) requirements, high costs, and limited access to therapies. These aspects underscore the pressing need for collaborative efforts to overcome these barriers and bring innovative treatments to those in need. Actually, cell therapy trials faced delays in FDA approvals, mainly regarding clinical trial applications (CTA), impacting the progress of innovative treatment methods. A significant development from the FDA took place in March 2023 with the creation of a super unit called the Office of Therapeutic Products (OTP). This resulted from the reorganization of the Center's Office of Tissues and Advanced Therapies (OTAP) by the Center for Biologics Evaluation and Research (CBER), which oversees the regulation of biological products, ensuring their safety, efficacy, and availability in the United States. The response aimed to manage the increased workload caused by the growing number of Cell and Gene Therapy (CGT) projects in biotech pipelines and the subsequent rise in trial numbers. The specialized OTP unit within CBER has dedicated teams for various products and processes, ensuring expertise and timely interactions with sponsors (See FDA press release). With the increasing number of CGT projects in pharmaceutical company pipelines, Tenthpin recently published an article delving into the intricacies of the supply chain for these trials. The article, titled “Untangling the Complexities of Cell and Gene Therapy Clinical Trials: A Supply Chain Perspective”, highlights challenges ranging from manufacturing to product delivery. Addressing the demand for an affordable and efficient CGT manufacturing and delivery approach is crucial. Pharma companies grapple with significant delivery challenges, especially for individualized cell therapies, where infrastructure, equipment, and expertise present notable bottlenecks. Outsourcing the production of these therapies to Contract Development and Manufacturing Organizations (CDMO) has proven effective, though businesses should carefully weigh the pros and cons to optimize benefits. Cost implications must be considered diligently to ensure affordability. How can pharma companies overcome major delivery challenges of cell therapy products? Which approach is believed to be the most effective strategy in terms of accessibility and costs? Point of Care (PoC) manufacturing emerges as a transformative solution, positioning the manufacturing process close to patients and significantly reducing logistical complexities. On-site production of therapies within hospitals and academic medical centers is specifically tailored for scenarios with limited opportunities for medicine storage or those requiring time-sensitive delivery. By promising shorter lead times from cell harvesting to therapy delivery, PoC manufacturing stands as an ideal solution to overcome challenges associated with the entire journey of autologous cell therapy trials and is particularly well-suited for critical clinical situations. Despite the evident benefits, life sciences companies express reservations regarding process standards, compliance, cost savings, regulatory approaches, and facility readiness. Nevertheless, the introduction of PoC manufacturing marks a revolutionary paradigm shift, strategically bringing the manufacturing process closer to patients and adeptly addressing logistical challenges. From an end-to-end perspective in clinical trials, this decentralized approach represents a cost-saving measure for trial sponsors. The streamlined logistics steps, in comparison to a centralized manufacturing approach, contribute to cost reduction and accelerate the entire journey. It expedites patient treatment by eliminating the need to ship materials to a centralized production site and then back to the patients. The traditional centralized model, with its complex logistics involving multiple steps and stakeholders to guarantee the cold chain, track the chain of identity, and maintain the chain of custody for each individual batch, is simplified with PoC manufacturing sites. Additionally, close real-time monitoring of trial progress and patient status, along with reduced dependence on biotech or pharma production slots for treatment scheduling, enables the treatment plan to better align with the clinical readiness of the patient. Collectively, these factors simplify the scheduling process, reduce waste due to higher chances of delivering the product in the appropriate quality, and improve overall coordination, leading to cost reductions. Undoubtedly, the application of PoC manufacturing in the cont

What's Your Reaction?