KITECH develops deformable energy storage device via laser technology

The joint research team, led by Dr. Chanwoo Yang and Researcher Seong Ju Park from Korea Institute of Industrial Technology(KITECH), along with Prof. Jin Kon Kim and Dr. Keon-Woo Kim from POSTECH, has successfully developed a compact energy storage device with excellent elasticity. This research was published in the world-renowned journal in the field of […]

The joint research team, led by Dr. Chanwoo Yang and Researcher Seong Ju Park from Korea Institute of Industrial Technology(KITECH), along with Prof. Jin Kon Kim and Dr. Keon-Woo Kim from POSTECH, has successfully developed a compact energy storage device with excellent elasticity. This research was published in the world-renowned journal in the field of electronic engineering, ‘npj Flexible Electronics’.

Credit: Korea Institute of Industrial Technology

The joint research team, led by Dr. Chanwoo Yang and Researcher Seong Ju Park from Korea Institute of Industrial Technology(KITECH), along with Prof. Jin Kon Kim and Dr. Keon-Woo Kim from POSTECH, has successfully developed a compact energy storage device with excellent elasticity. This research was published in the world-renowned journal in the field of electronic engineering, ‘npj Flexible Electronics’.

Beyond foldable and rollable devices, the era of stretchable IT devices is arriving. For these devices, the development of small, elastic energy storage devices is essential. In this respect, micro supercapacitors (MSCs) are gaining attention as very small volumes that can power such electronic devices. However, the solid metals commonly used as current collectors, such as gold (Au), have inherently limited stretchability, significantly restricting their potential for deformation.

In this study, the team selected gallium-indium liquid metal (EGaIn) as the MSC current collector. EGaIn has very high conductivity and, due to its liquid nature, is easily deformable. However, shaping it has posed significant technical challenges. To overcome this, the team devised a method of patterning EGaIn using a laser. They successfully used the intense energy of the laser to pattern EGaIn simply and precisely, applying it effectively as the MSC’s current collector.

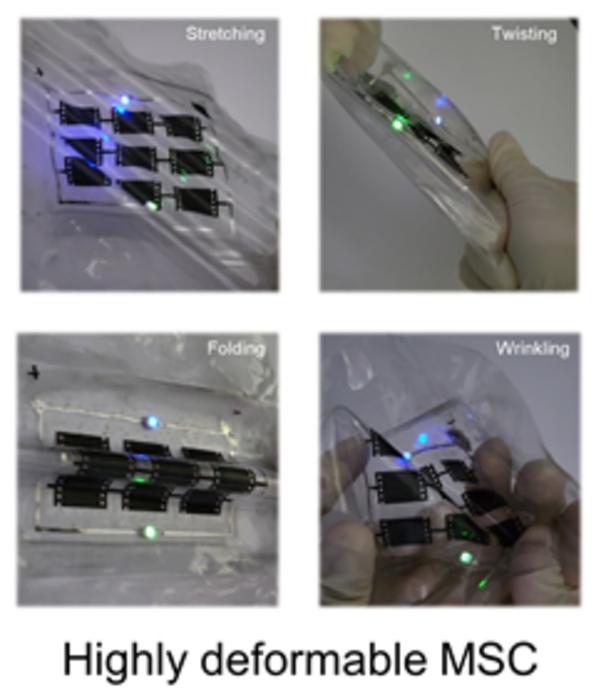

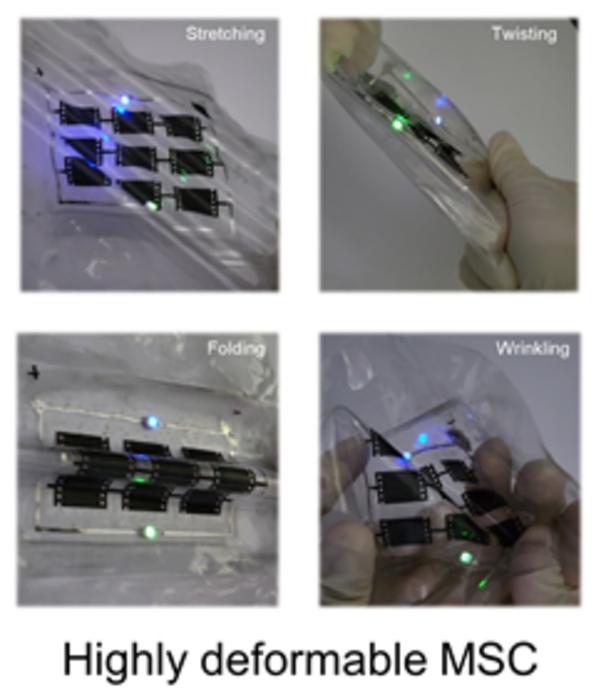

Based on this technology, the research team was able to create an MSC that could be stretched and shrunk over 1,000 times without any loss of energy storage performance. Furthermore, this device demonstrated stable energy supply capability even when twisted, folded, or crumpled.

Dr. Yang stated, “Laser technology allows for precise work while also speeding up the process,” and expressed his hope that “this research will be useful in various industrial fields and contribute to the development and commercialization of elastic energy storage devices.”

###

This research was supported by the Development of Root Process Technology for Production Flexibility at KITECT and the Creative Research Project of the Ministry of Science and ICT and published in the articles of npj Flexible Electronics (IF: 14.6 & JCR: 2.0%), Mar 2024.

KITECH, founded in 1989 as an affiliate of the Ministry of Commerce and Industry, has emerged as a premier comprehensive applied research institute in Korea. KITECH is addressing the digital transformation challenges confronting local industries, both internally and externally, by leading the charge in supporting Korean manufacturing innovation globally.

Journal

npj Flexible Electronics

DOI

10.1038/s41528-024-00306-2

Article Title

Deformable micro-supercapacitor fabricated via laser ablation patterning of Graphene/liquid metal

Article Publication Date

14-Mar-2024

What's Your Reaction?